Casting Expo

The National Exhibition and Convention Center (Tianjin) was held grandly. With its new concept and broad exhibition scope, it has brought profound impact to the industry and pointed out a new learning direction for companies such as DINSEN.

This year's Casting Expo actively responded to the call for global sustainable development and carried out the concept of green and low-carbon throughout. Under the background of increasing global attention to environmental protection, the foundry industry, as a traditional industrial field, faces huge challenges in energy conservation and emission reduction. At the exhibition, many companies displayed a series of green casting technologies and equipment, such as new smelting equipment, which greatly reduced energy consumption and exhaust emissions by optimizing energy utilization efficiency; and adopted environmentally friendly casting materials to reduce the use of chemicals that are harmful to the environment. This concept has prompted foundry companies to re-examine their own production processes, promote the entire industry to transform into a resource-saving and environmentally friendly one, and lay a solid foundation for the sustainable development of the foundry industry.

Faced with increasingly stringent environmental protection requirements and market demand for green products, DINSEN realized the importance of green production technology. By visiting the Casting Expo, DINSEN can learn the industry's leading green casting technologies, such as efficient exhaust gas treatment technology and the application of environmentally friendly casting materials. DINSEN can learn from these technologies to optimize its own production processes, reduce energy consumption and pollutant emissions, and improve the company's environmental performance.

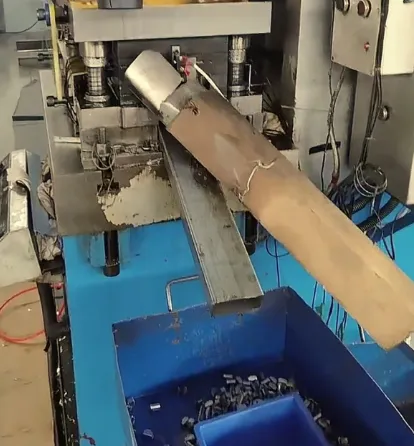

At the Casting Expo, DINSEN gained an in-depth understanding of the working principles and application effects of various intelligent casting equipment. DINSEN demonstrated the automated molding production line of hose clamps, automated stamping, welding, assembly and tightening, which improved the production efficiency and product quality stability of couplings. DINSEN actively responded to the development trend of the future manufacturing industry by improving the company's intelligence level.

The Casting Expo, with its new concepts and broad exhibition scope, has brought new technologies, development opportunities and thinking to the foundry industry. For DINSEN, this is a rare opportunity to learn and improve. By learning new concepts and leveraging cooperative relationships, DINSEN will continue to work hard in green production, intelligent manufacturing and industrial chain collaboration to enhance the company's comprehensive strength and contribute to the development of the foundry industry.

#lowcarbon, #foundryindustry, #foundrytechnology, #foundrymaterials, #foundryequipment #hoseclamps #couplings #pipeline #pipecoupling #dinsen

-

Features and Applications of Lightweight CouplingBeritaMay.20,2025

-

Metal Processing, Taking Clamp as an ExampleBeritaMay.19,2025

-

Grip E Clamp for ConstructionBeritaMay.15,2025

-

Main Application Range of DINSEN Pipe CouplingBeritaApr.30,2025

-

How to Choose the Right Pipe Couplings?BeritaApr.28,2025

-

Mengapa DINSEN Menghantar Produk Cengkaman Berbeza Untuk Pesanan Yang Sama?BeritaApr.02,2025

-

Pengapit Kolar Cengkaman DINSEN Mendapat Pujian daripada SwitzerlandBerita28 Mac 2025